Stop disruptions to production as a result of PLC system security breaches

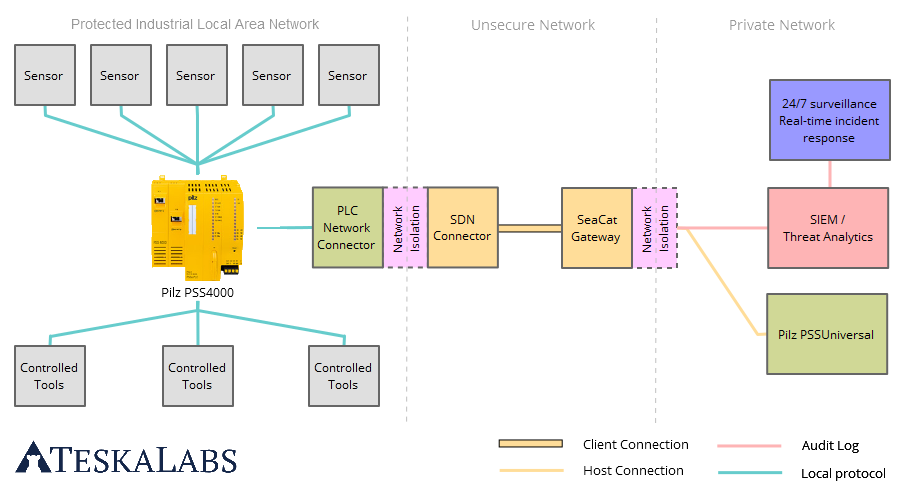

Attacks targeted at susceptible PLC systems that regulate important business operations and infrastructure could lead to an interruption of production in work facilities. These attacks may also result in a loss of data, eradication of tangible assets, and the growth of substantial production expenses. A PLC breach has the capacity to negatively impact manufacturing plants and factories. Our technology singles out such infrastructures and protects them from unauthorized access, letting companies maintain functionality and communication to central control systems, for example, Siemens Simatic or Pilz PSSUniversal. This allows businesses to maintain PLC systems without being concerned about violations of their production facilities.

Stop illegal access and changes to important data

Pumps, engines, and other industrial machinery need specific input from controllers and sensors in order to keep manufacturing process running smoothly. If this data is modified or corrupted, equipment may be inhibited, completely halting production. Our technology safeguards the data source and stops any attempts to alter communication, or efforts to connect to untrusted devices and systems. We protect the confidentiality, integrity, and accessibility of critical information.

Compliant with security standards and industry regulations

PLC control systems prepare data received from sensors (like pressure levels, temperature, humidity, etc.), to regulate crucial processes and tangible assets (like equipment and engines). Therefore, PLC control systems require specific measures of security that adhere to meticulous requirements and industry standards. Compliance with such regulations necessitates regular security implementation and processes throughout the entire organization. Our technology follows rigorous security standards regarding data-in-motion authentication, protection, public key infrastructure and the like, in order to help companies comply with regulations.

Lessen the effect of a security breach

Smart factories and manufacturing plants require dependable and secure PLC systems and cannot afford to let attacks happen. Without 24/7 tracking, it’s not possible to monitor suspicious activity, isolate potential threats, and quickly react to cyber attacks. Our technology provides system administrators and operators with the ability to catch threats, monitor system-related activities, and prevent security breaches. Additionally, our experts remotely monitor PLC systems and offer exact, real-time responses to every incident. With a reliable security monitoring system and incident response service in place, manufacturers can relax knowing they can operate complex networks of critical PLC-controlled tangible equipment and PLC systems securely.